25.000 Tons./Year

Grey, nodular and vermicular cast iron from 0,05 Kg. up to 350 Kg.

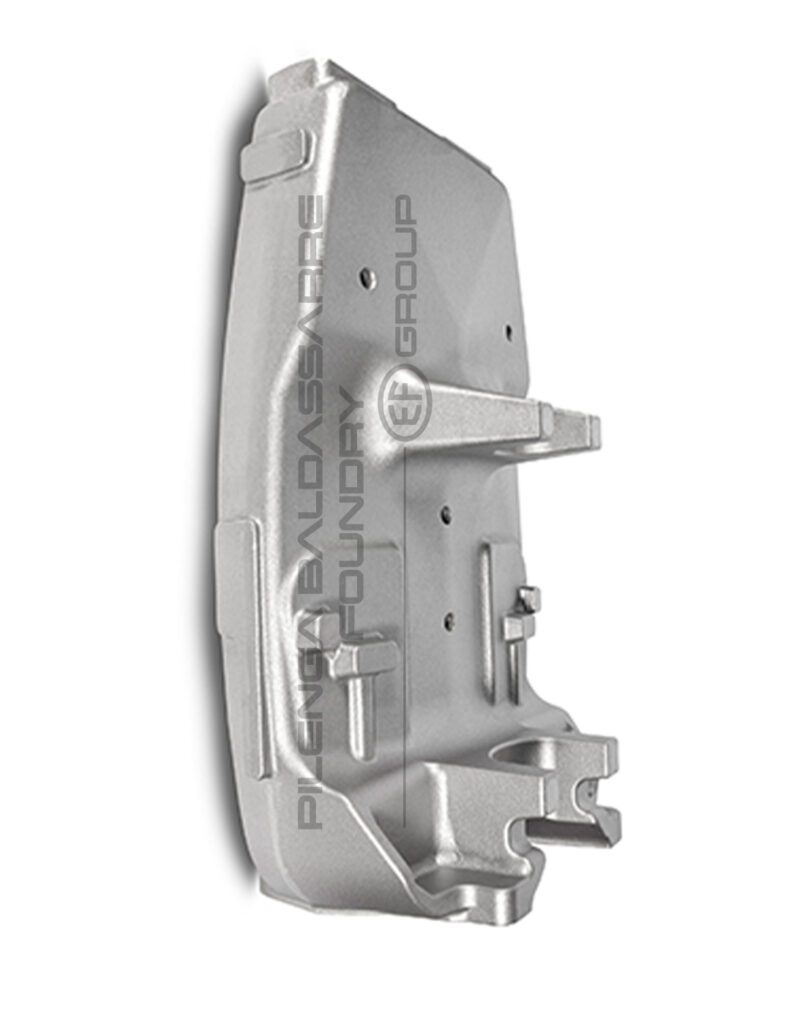

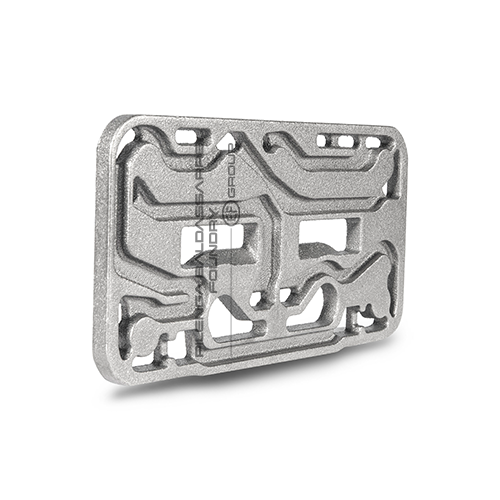

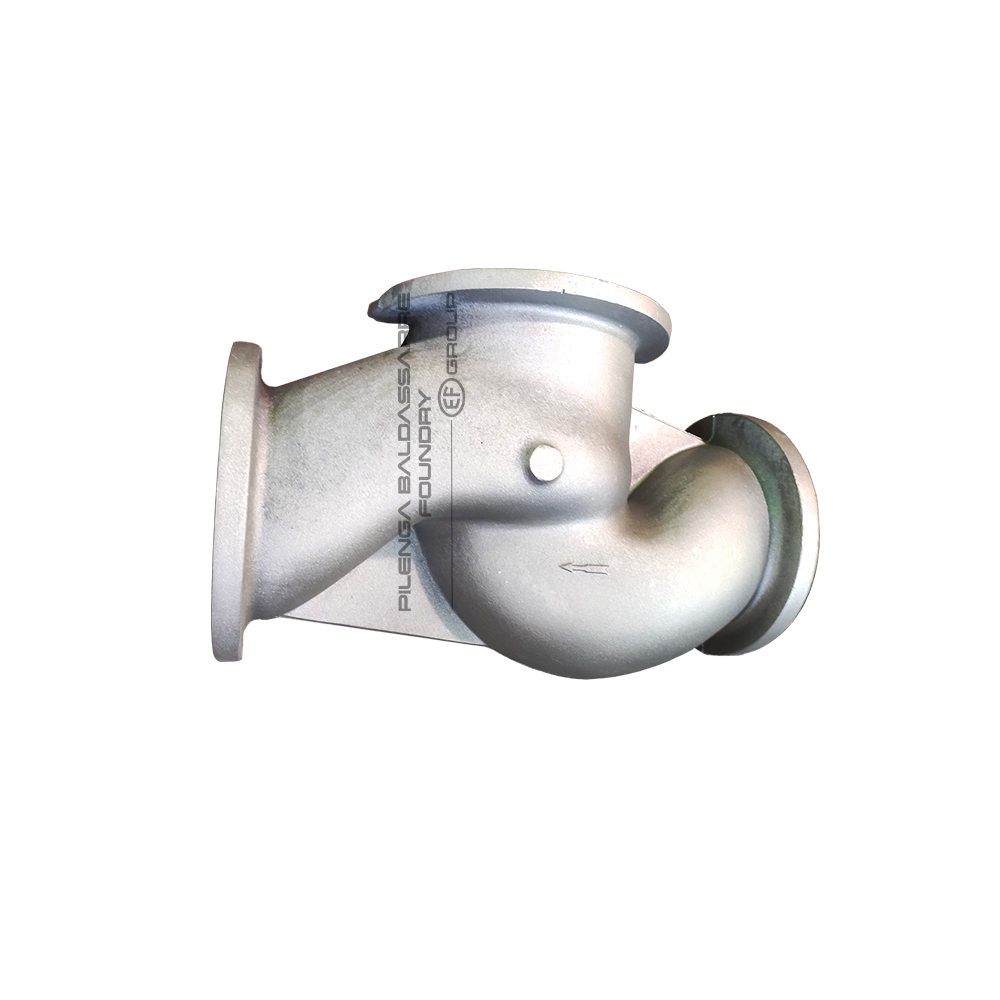

Production of components for automotive/trucks, industrial vehicles, earthmoving machines, agricultural, compressors, hydraulics and various other sectors.

Pilenga Baldassarre Foundry S.r.l.

cross-market-foundry

We create value for our customers through an extensive and innovative range of products and services developed with a sustainable and responsible approach.

Production takes place in the plant in Lallio, Bergamo, in a 40,000 sq. m. area ( 20,000 covered ) with about 100 employees.

The installed capacity of 25,000 tons/year is characterized by great production flexibility: we are able to efficiently produce castings from 0,05 kg up to 350 kg.

Technical information

40.000 sq. m. - 20.000 sq. m. covered

Moulds 600 x 480 x ( 200/360 )

Moulds 750 x 535 x ( 200/360 )

Casting weight 0,05 - 25 Kg.

5 Electric furnaces of 28 Tons each

Flasks 1.400 x 1.200 x ( 300 + 400 )

Casting weight 30 - 350 Kg.

production flexibility

We are a Cross-Market-Foundry

The company cuts across all industries due to its marked production flexibility (we produce castings from 0,05 to 350 kg in grey, spheroidal and vermicular cast iron). Quick and punctual deliveries are distinctive factors.

Sustainable production

77% of the metal feedstock comes from recovered materials

95% of waste generated becomes raw material in other industrial processes

Our way to sustainability

Environment and Circular Economy

The activity of the foundry highlights in a good part of its processes the “circularity” of the economy, given in good part by the recycling industry and all the supply chains involved.

A large part of the raw material used in our production processes comes, in fact, from ferrous scrap and the reuse of waste from the same processes.

We have been applying for years a continuous, preventive and integrated environmental strategy toward processes, products and services in order to increase the overall efficiency and reduce the impact on ‘environment and man in view of circular economy.

Industrial innovation

Since its acquisition by the Company in 2016, Pilenga Baldassarre Foundry has undergone a major restructuring plan and upgrade of production technologies.

RESTRUCTURING PLAN

RESTRUCTURING PLAN: some example

Modernization of the forming line

Modernization of the sand preparation and recovery plant. View time-lapse video of the line installation.

New filtration plants

Reduce diffuse emissions and capture emissions from the end-of-melt process

Ferrous part recovery from dust

A major plant was installed in 2022 that enables the recovery of the ferrous part from dust from production processes.

Why Pilenga Baldassarre Foundry?

the photos are an example of our production

Cross-Market

industrial transversality: ability to be suppliers for extremely varied industrial sectors

Co-Design

Wide ability to develop custom CAD CAM projects and in co-design mode

Fast prototypes

Rapid development of standard and custom prototypes

Time-to-market

Speed of execution of the entrusted projects. Quality and delivery within the agreed times

Project Manager

A dedicated Project Manager for every aspect of production

Sustainable Production

Recent investments have been oriented towards the responsible use of resources

Full Service Partner

We are ready to provide a customized solutions for you

Certifications

To ensure absolute compliance with customer requirements, our production Quality System team constantly verifies the compliance of processes with ISO 50001:2018 – ISO 9001:2015 – ISO 14001:2015 – ISO 45001:2018 – IATF 16949:2016 standards through audits and re-certifications. This ensures that the Pilenga Baldassarre Foundry will deliver on its promise to deliver reliable and durable high performance products.

Code of Ethics

Pilenga Baldassarre Foundry S.r.l. is an industrial company which, due to its structure and size, the activities it manages and its links with the local area and the environment, plays a significant role with respect to the market, economic development, environmental protection and the well-being of the communities in which it is present, operating in a variety of institutional, economic, political, social and cultural contexts.

Environmental, Energy, Health and Safety Policy

Pilenga Baldassarre Foundry, producing for prestigious customers in various sectors, undertakes to conduct its activities in order to achieve excellent results in the environmental, energy, safety and health of workers fields (Environmental, Energy, Health and Safety EEHS – Environment, Energy, Health and Safety), in the protection of the ecosystem in which we operate and according to the provisions indicated in the company Code of Ethics.

Quality Policy

We consider Quality the main success factor in competing with the competition. For these reasons we have implemented a Quality Management System according to the requirements of the ISO 9001 standard and the IATF 16949 Technical Specification in order to improve the management of business processes and meet customer requirements. The system is planned through the analysis of risks and opportunities, believing that this type of approach makes the company proactive and non-reactive, preventing or reducing unwanted effects and promoting continuous improvement.

Contacts

Share page with: